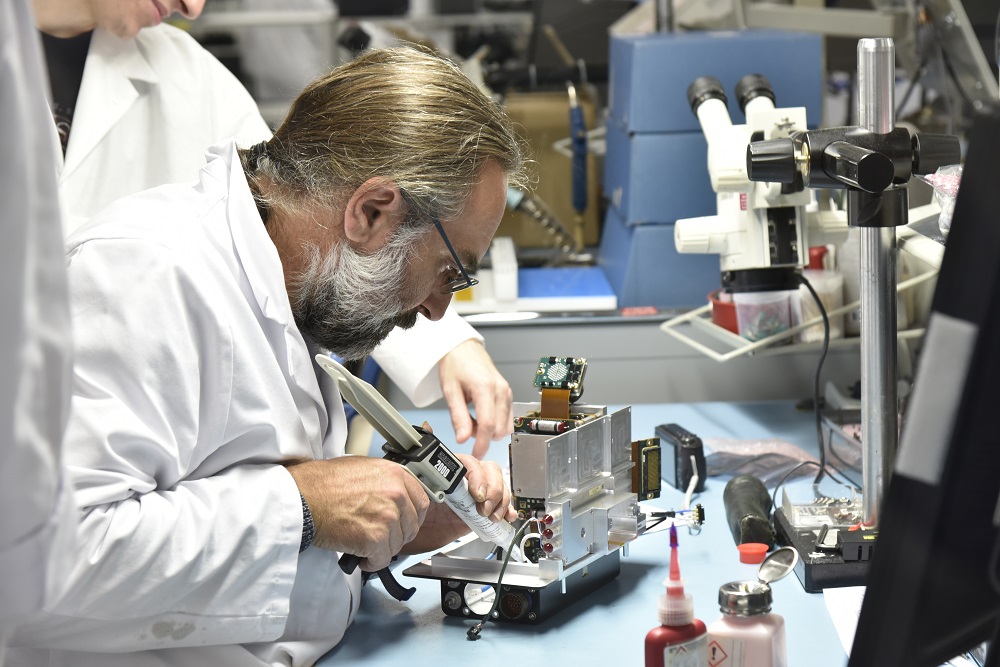

OUR MANUFACTURING METHODS

The analysis of the definition of the product, allows us to propose a synoptic of production control by detailing the manufacturing levels. After, we establish the ranges which correspond to an optimized operating procedure. They detail the manufacturing times and the qualifications required for each operation to achieve our quality, cost and deadline objectives.

Our method preparers thus produce the machine programs and the instruction sheets for the workshops. This operating procedure aims, step by step, to allow our operators to produce independently. Our operators are trained and qualified to international and internal technical standards. In addition, we provide specific field support for each implementation of new products, in order to integrate improvement proposals as soon as possible.

The production stage of a prototype is capitalized by our technicians and engineers in a first assembly report. This document makes it possible to propose process optimizations and a critical analysis of the definition from a manufacturability point of view. Our expertise allows us to cover board manufacturing technologies from the SMT transfer to the gluing and tropicalization steps, the manufacture of wired interconnections and the integration of electronic boxes.

This first assembly report or “CRPASS” is shared between the production teams and the design teams of our customers. It’s an opportunity to meet and discuss constraints and make the product more reliable.

The methods teams at Matra Électronique guarantee the definition and the correct application of the manufacturing process for our customers’ equipment.

Mathieu Ruffiot, Head of Methods Department.

Discover